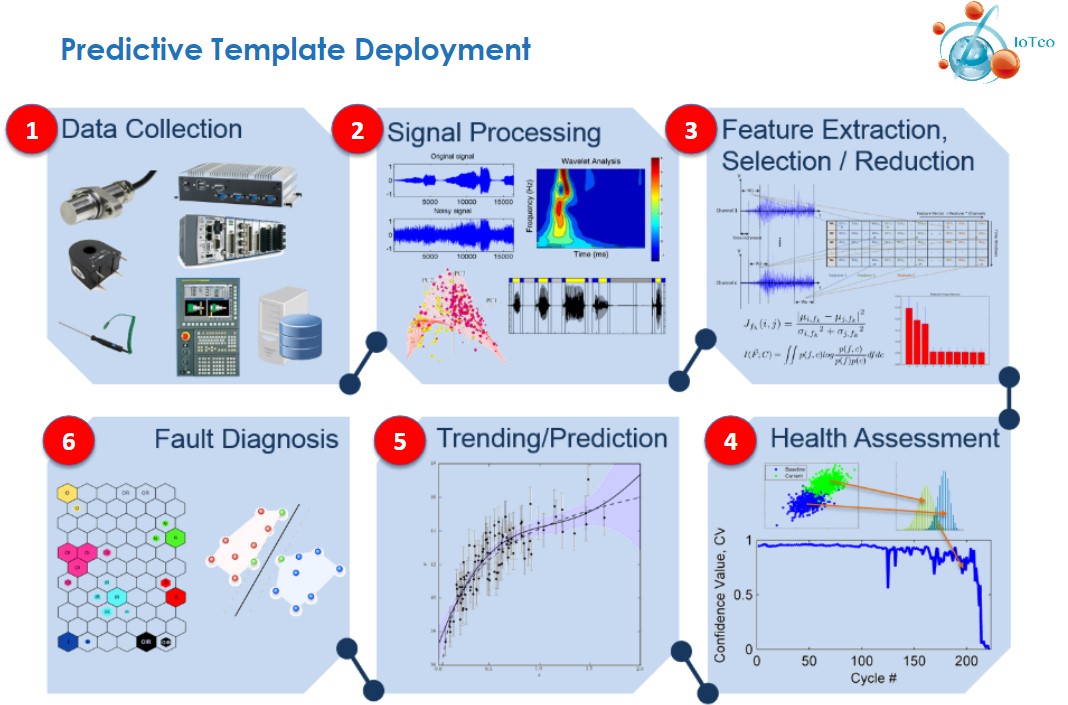

Many companies offer predictive maintenance solutions, but unlike other companies, our approach is faster, more cost effective and requires fewer resources. We can achieve this using a variety of “templates” that follow a six-step process. These steps include:

Data collection. We collect data from multiple sources, including third-party sources, for any given time period. The result is an intentional and effective data acquisition approach, which only yields the necessary information for analysis and producing real-time, impactful results.

Signal processing. We remove outliers and “noise” to get clean data.

Feature extraction. We then convert the raw, clean data into meaningful features that we use to “train” our AI algorithms.

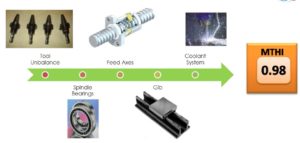

Health assessment. Our AI machine learning model creates a fingerprint of a healthy and unhealthy machine. Our model compares machine performance to these fingerprints to assess machine health over time.

Trending/prediction. Our models compare machine health over time to identify trends and calculate remaining useful life to determine when the machine will likely fail, down to the day, number of cycles and number of shifts.

Fault diagnosis. Once our models determine a failure is likely to happen, we can determine the root cause of the failure so maintenance teams can respond quickly before the machine experiences downtime.